F600 HP – HIGH PRESSURE COMPACT LEAK DETECTOR FOR PRODUCTION TESTING

Without any doubt the smallest high pressure leak detector on the market. The F600 HP is equiped with the technical innovations of the 6 series and allows high pressure leak testing at a very competitive price.

F600 HP : APPLICATIONS

Catheters, refrigeration parts, oil radiators, HP tubes and pipes, valves, hydraulic brakes…

F600 HP : FEATURES

• Pressure decay leak testing from 5 to 1000 kPa

• Range of measurement from 20 to 200 bar

• 128 programs

• Mechanical regulation 5 MPa/ 10.0MPa/ 17.0 MPa / 20.6 MPa

• Electronic regulation 4 MPa / 5 MPa

TEST MODES :

• Flow units (sccm, mm3/s, cm3/s, cm3/min, cm3/h…)

• Desensitized Test and others, depending on your applications

ENVIRONMENT :

ROHS standard

FLEXIBLE COMMUNICATION FORMAT :

•RS232: printer, modbus RTU

• Slave USB: PC supervision (WinAteq 300, sesame)

• Master USB: USB key to transfert (parameters, results, …)

• 6 inputs/ 6 outputs 24 V programmable for external automation

MEASUREMENT CHARACTERISTICS :

| Pressure Range | Measurement range | Accuracy |

|---|---|---|

| 5 MPa Max (50 bar) | 0.01 – 5.00 kPa | +/- 1.0% Rdg +1% F.S. |

| 10 MPa (100 bar) | 0.01 – 10.00 kPa | |

| From 2 to 20 MPa

20 to 200 bar |

0.01 – 50 kPa | |

| 0.01 to 100.00 kPa | ||

| 0.01 > 100.00 kPa | ||

| 0.1 – 500.00 kPa | ||

| 0.1 – 1000.00 kPa |

Measurement range: From 10 % to 100 % of the full scale.

F600 HP : SPECIFICATIONS

- PHYSICAL

- Weight : 7 Kg

- Dimensions : (WxHxD) 250x150x360 mm

- ELECTRICAL SUPPLY

- 24VDC/2A or 100-240VAC/50W

- TEMPERATURE

- Operating : + 5°C at + 45°C

- Storage : 0°C at + 60°C

- INTERFACE

- Graphic color screen with simple and intuitive menu-driven operator controls

- SMART KEY : programmable key with user’s functions

- AIR SUPPLY

- Command 4/6 bar

- Pressure 1 or 2 bar > test pressure

- Clean and dry air

- Air quality standard to be applied (ISO 8573-1)

- Command 4/6 bar

F600 HP : FACTSHEETS

Detailed information about the F600 HP including features, specifications, etc.

F600HP : TECHNOLOGY

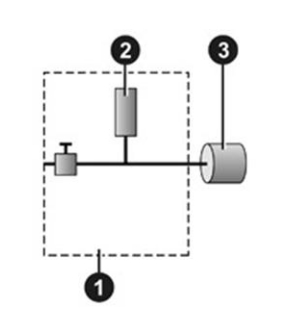

As a stripped down version of the previous technology, standard pressure decay compares the pressure on the part with the atmospheric pressure.

This technology is used when the application does not require a very high accuracy or a very fast cycle time. The method used is based on the measurement of a small variation or drop in pressure with a piezzo sensor.

Leak test and Desensitized Mode

The test pressure is applied to the input of the test part 3.

The measurement is performed by the pressure sensor 2.

1 Device

2 Pressure sensor

3 Part under test